Copy of Automation & Drive

Automation & Drive

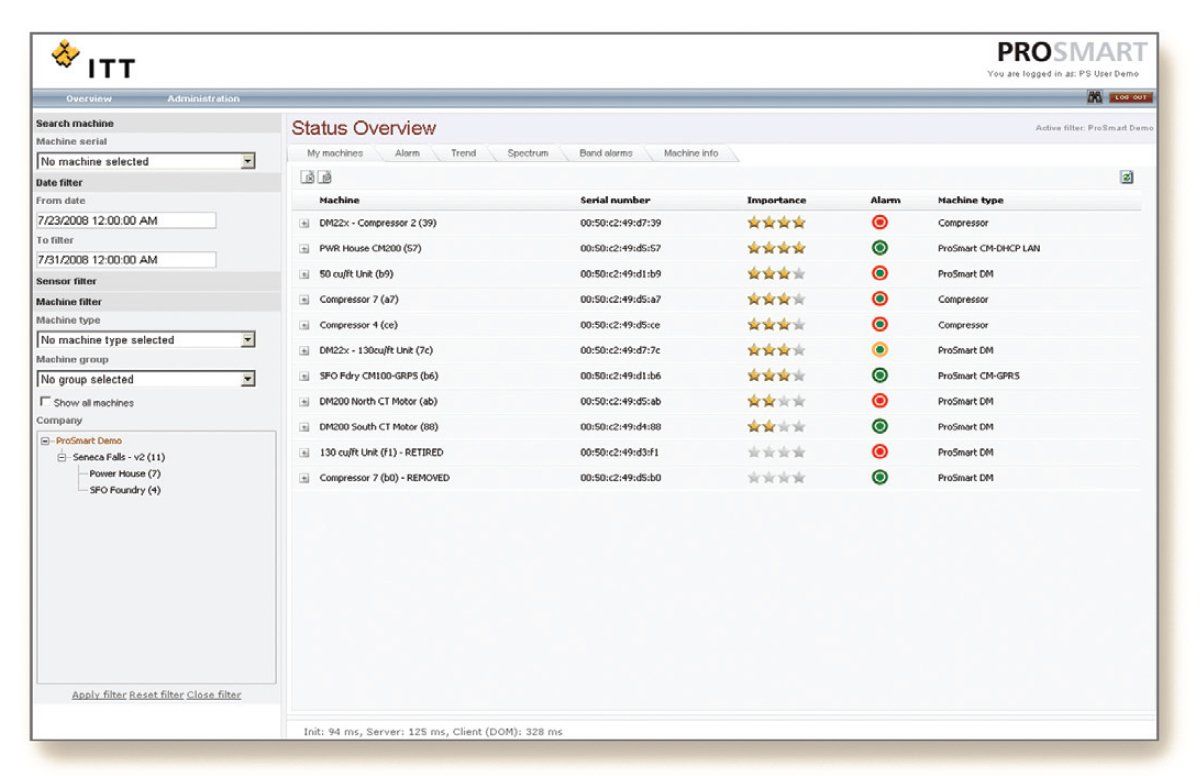

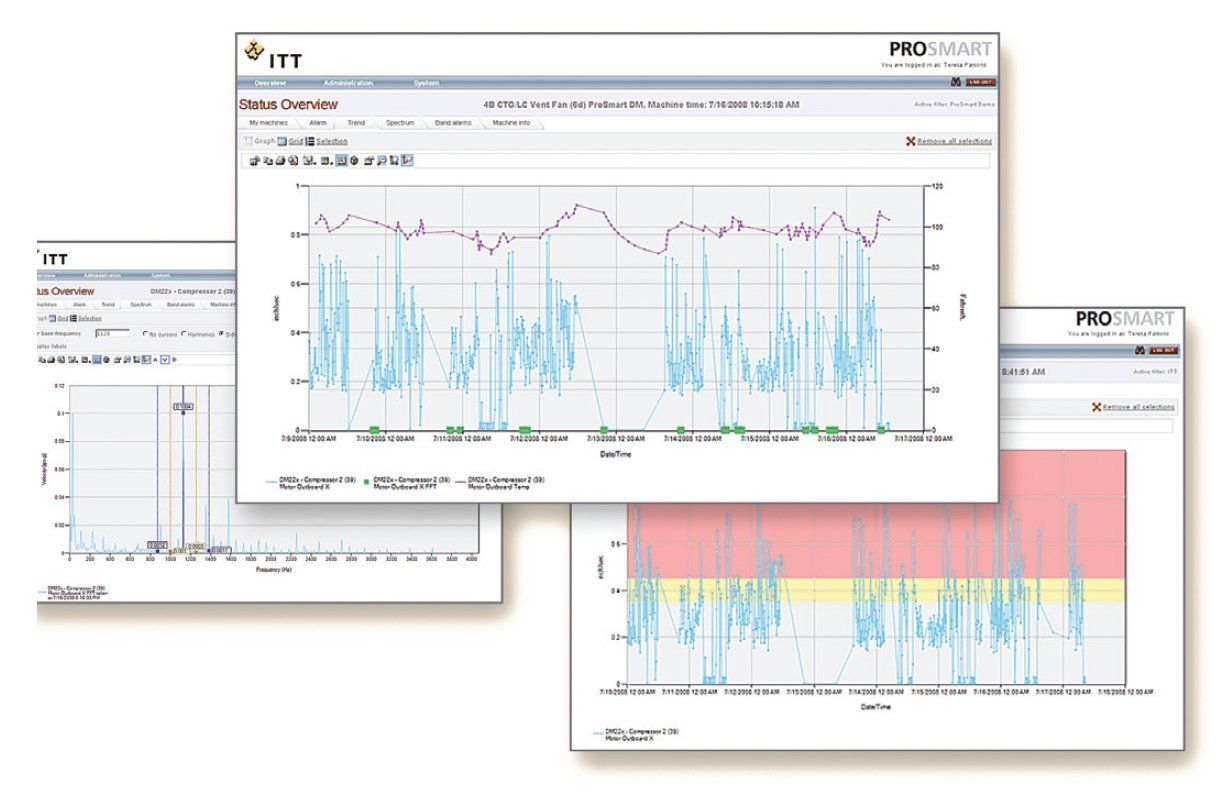

ITT PROSmart

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Newsletter

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later.

Please try again later.

ProNet Interface Emulator

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

ITT PumpSmart

pump control systems provide real-time control and protection of your centrifugal pumps while also providing valuable process insight. By protecting against unplanned pump failure due to process upsets, we can keep your process running longer and eliminate unplanned repair activities. By Right-Sizing your pumps to your system, we can reduce not only your energy consumption, but the wear and tear on your process system.

11-01.png

Sensorless Flow Control.

Patented feature allows accurate process flow with no flow meter...

Flow Economy.

PumpSmart PS200. Calculates your process efficiency by flow of product versus energy consumption (kW). Allows the operator to know the best operating point for their pump.

Guaranteed Pump Protection

- The PS200 provides the operator the ability to set protection for low flow, no-flow, run-out and cavitation. The patented logic once set up, can alarm or warn operations of process upsets. Ask about the ITT Goulds guarantee when using a Goulds Pump ® model and PumpSmart PS200 variable speed system.

Multi-Pump Control

– The PS200 has the ability to control up to 4 pumps in parallel for automatic lead/lag changeover, redundancy back up, synchronized torque control while still communicating to a fieldbus or DCS system. Whether the plant wants to monitor or take full control, the PS200 has the solution for multi-pump systems!

Options and Engineered Solutions

- The PS200 is available in a low harmonic configuration which guarantees to meet IEEE519 harmonic specifications and requirements for certain industries requiring low harmonic distortion on the utility line. Also available are packaged systems with many different style enclosures and options that surpass most local sources!

Low Voltage Drives

Medium Voltage Drive

SPOC

Well Optix SCADA Software

SPOC HPS Series Drive

Disposing of saltwater through injection applications puts incredible stress and wear on the pump. Traditional solutions run the pump at full speed and use a valve to choke back pressure to the optimum level. The SPOC HPS drive offers an alternative solution that greatly reduces wear on your system, helping you operate more efficiently.

The HPS variable frequency drive controls the speed at the pump, allowing you to leave the valve open at all times, reducing wear and failures within the system. The drive’s simple interface allows you to control and monitor your tank levels, vibration sensors, intake pressure and discharge pressure. You can now control the pump at the widest possible range.

With the HPS drive, you can:

- Use traditional oilfield switches and gauge controls, or fully automate the pump system with more accurate pressure transducers with analog outputs.

- Reduce peak demand charges from utility and energy consumption when compared to across-the-line starters.

- Reduce inrush currents to the name-plate amps of the motor; that is seven to 12 times less than starting the H-Pump with an across-the-line starter.

- Save money by running the pump at the optimal speed rather than just an on/off control.

West Texas Region

South Texas Region

North Texas Region

Gulf Coast Region

New Mexico Region

Artesia, NM

Oklahoma Region

Oklahoma, OK:

Corporate Headquarters & International Sales - Odessa, TX

3800 E 42nd Street, Suite 333

Odessa, TX 79762

Phone: 877.362.0468

© Knighten Industries